Advanced 3D Automatic X-Ray Inspection | V810 S2EX

Overview

|

What's V810 S2EX?V810 is "3D Automatic X-ray inspection System" that corresponds to the double side mounting SMT-PCB that is not able to be checked by a transmission-type X-ray machine. It has the ability to detect a wide range of defects, and It have 100% complete defect detection capability in the Hip-defective. And, it is the inspection machine of world's highest level that combines the ability of the ultra-fast test speed and the lowest false call positives further. |

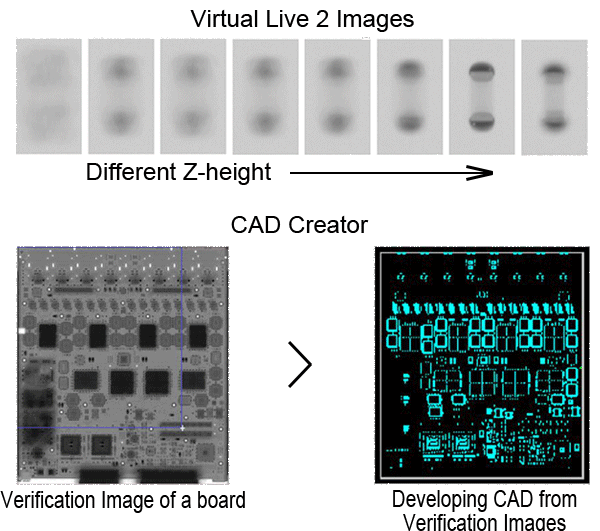

Ease of ProgrammingCustom focus region for POPReduce the setup of POP slice height and improve focus accuracy on POP.Intelligent Initial LearningAuto learning feature that reduces program setup time.Package LibraryIntelligently populate package information across production board.Virtual Live 2Failure analysis tools to view multiple slice image instantly.CAD CreatorCapability to create CAD from Printed Circuit Board (PCBA) verification Image or SMT mounter machine's info. |  |

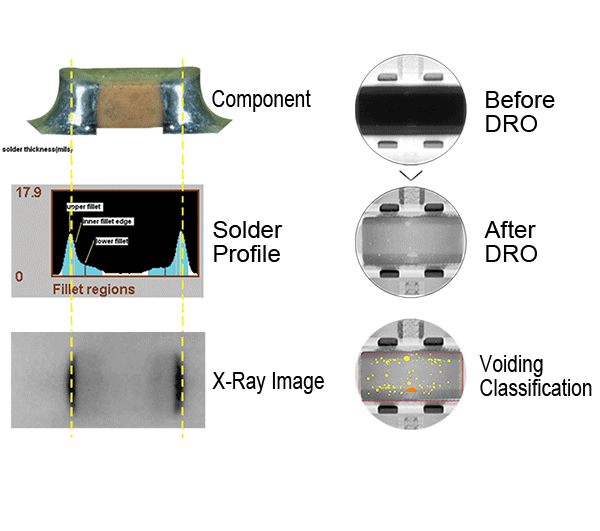

Advanced TechnologiesProprietary Hybrid Auto Focus TechnologyIntelligently focus on desired Z-height without any mechanical movement from X-ray or stage.Solder Profile CharacteristicProvide thorough system information for troubleshootingDynamic Range Optimization (DRO)Produce high quality X-Ray images on very heavily shaded components and non-uniformly shaded component. |

|

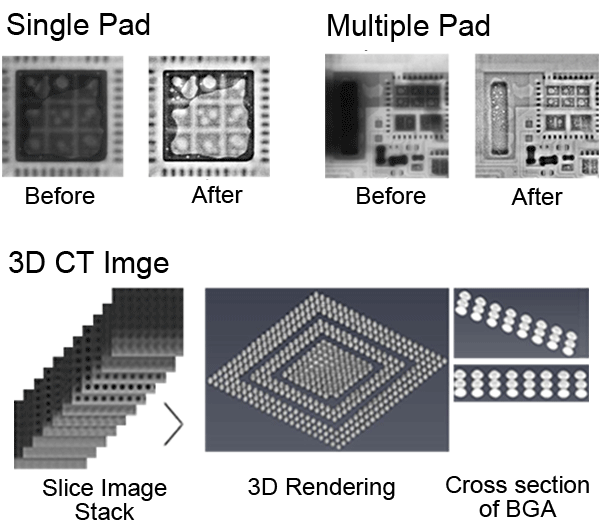

Image QualityImage EnhancementMulti image enchancer techniques to improve image clarity on multi layers component for void detection and visual verification.3D CT Image3D modeling viewer at V810 and VVTS repair station.Point Spread Function (PSF)Improve image clarity on 2.5D and help operator to make better judgement. |

|

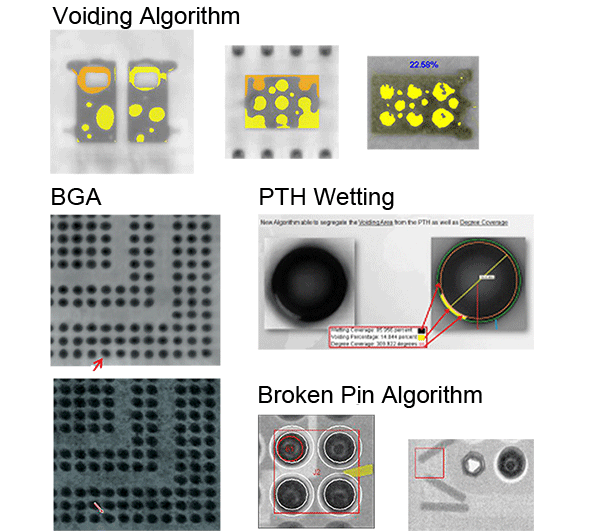

Improve Test CoverageAdvanced algorithm with more than 20 joint types selestion. Phase Shift Profilometry (PSP 2)Improve accuracy and test coverage on 100% Pressfit and PTH board.New Voiding AlgorithmImprove the accuracy of detecting various type of voids on the component especially on large pad greater than 1 inch.PTH DetectionPTH wetting fully compliance with IPC wetting standard. Can define up to slices to determine barrel fill percentage on PTH.BGAAdditional 3 user-defined slices to improve HIP detection.Broken Pin AlgorithmCapability to detect broken pin within PTH area and its surrounding area. |  |

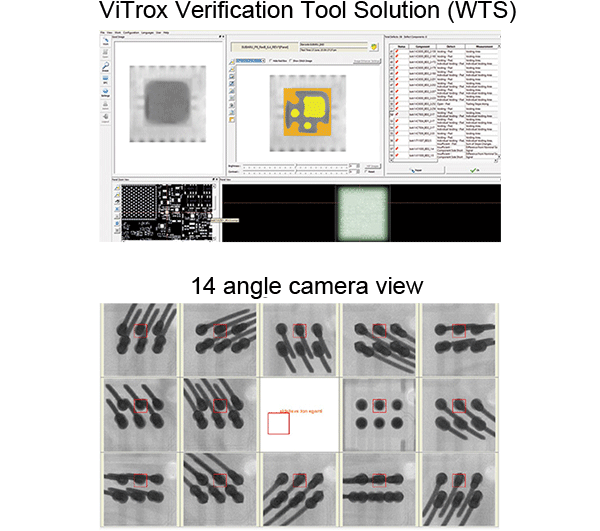

Ease of Buy OffViTrox Verification Tool Solution (VVTS) Repair StationA clear and user friendly defect verification tool allows the operator to review inspection results easily and accurately.Auto RejectAutomatically reject defective joints without operator buyoff.Good Image ComparisonEffectively improve operator disposition experienceDiagnostic ImageHighlightvoiding area and show voiding area percentage.2.5D PTH & BGA Angle ViewProvide most angle view images in market. |  |

Specification

Board Dimensions

| Maximum panel size | 482mm X 610mm (19" x 24") |

|---|---|

| Minimum panel size | 76mm X 76mm (3" x 3") |

| Maximum panel inspectable area | 474mm X 610mm (18.7" x 24") |

| Maximum panel thickness | 7 mm (276 mils) |

| Minimum panel thickness | 0.5mm (20 mils) |

| Panel warp | Downside < 3.0mm; Upside < 1.5mm (PSP) |

| Maximum panel weight | 4.5kg |

| Minimum panel weight | 0.03kg |

Clearance

| Board top clearance | 50mm @ 23um resolution 38mm @ 19um resolution 11mm @ 11um resolution (calculated from board top surface) |

|---|---|

| Board bottom clearance | 70mm |

| Panel edge clearance | 3mm |

| Panel width tolerance | 3mm |

| System resolution | 11um/19um/23um |

| 100% Press-fit testability | Yes (With PSP2 feature) |

| Maximum acceptable panel temperatures | 40 Deg C |

System Dimension

| Footprint | 1566mm (W) x 2145mm (D) x 1972mm (H) |

|---|---|

| Weight | ~3500kg |

| PRODUCTS |

.png)